Technologies

From the outset, the following waste and wood biomass products considered for potential energy recovery have been the following:

Timber

Organic agricultural waste

Used vegetable oil

Solid faecal waste (human and livestock)

“There are two processes for the conversion of biomass to energy. They are either thermo-chemical or biological”[1] and it would appear that each of the biomass products under consideration above would fit into one of these two types of processes. Liquid bio-fuels are possible by-products of the conversion process and are viewed as transport fuels. Used vegetable oil will be considered in a similar way to any these bio-fuel by-products and will therefore not affect the decision on which processes to employ to accept and convert the initial waste or wood products. This therefore leaves three other sources of biomass which can be dealt with using the following type of process:

Waste/Wood Product Type of Conversion Possible Processes

Timber Thermo-chemical Combustion, Gasification, Pyrolysis, Liquefaction

Organic Agricultural Waste Thermo-chemical Combustion, Gasification, Pyrolysis, Liquefaction

Solid faecal waste Biological Anaerobic Digestion

Timber

Organic agricultural waste

Used vegetable oil

Solid faecal waste (human and livestock)

“There are two processes for the conversion of biomass to energy. They are either thermo-chemical or biological”[1] and it would appear that each of the biomass products under consideration above would fit into one of these two types of processes. Liquid bio-fuels are possible by-products of the conversion process and are viewed as transport fuels. Used vegetable oil will be considered in a similar way to any these bio-fuel by-products and will therefore not affect the decision on which processes to employ to accept and convert the initial waste or wood products. This therefore leaves three other sources of biomass which can be dealt with using the following type of process:

Waste/Wood Product Type of Conversion Possible Processes

Timber Thermo-chemical Combustion, Gasification, Pyrolysis, Liquefaction

Organic Agricultural Waste Thermo-chemical Combustion, Gasification, Pyrolysis, Liquefaction

Solid faecal waste Biological Anaerobic Digestion

Thermo-chemical Processes

Combustion

Direct Combustion/Steam Turbine System

Biomass with a low moisture content is often used a feedstock for combustion. This “refers to the rapid oxidation of the feedstock as it is exposed to high heat”[2] in a boiler where steam, under high pressure, is passed through a turbine which powers a generator. The main types of combustion processes are; “fixed-bed combustion, fluidised-bed combustion and dust combustion”[2].

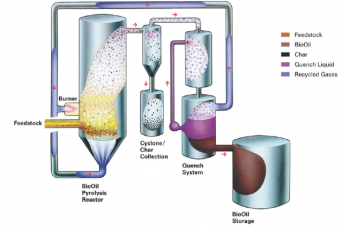

Pyrolysis

Pyrolysis Process

Here, “heat is used to chemically convert biomass into fuel. It occurs when biomass is heated in the absence of oxygen”. A by-product of pyrolysis is “pyrolysis oil that can be burned like petroleum” along with biochar[3].

The pyrolysis of wood is a thermal decomposition carried out in a closed furnace with very limited air input (less than 10% stoichiometric)”. To start the process, a heat source is required, but when the temperature in the furnace “reaches more than 250°C, the reactions that take place are exothermic and the process is self-maintained up to 600°C”. There are some by-products of the pyrolysis of wood;

By-products Physical state Brief Description

Charcoal Solid

Tar Liquid Highly viscous liquid

Pyroligneous liquor Liquid Condensation of vapours

Gasses, mainly CO and CO2 Gas

[4]

The pyrolysis of wood is a thermal decomposition carried out in a closed furnace with very limited air input (less than 10% stoichiometric)”. To start the process, a heat source is required, but when the temperature in the furnace “reaches more than 250°C, the reactions that take place are exothermic and the process is self-maintained up to 600°C”. There are some by-products of the pyrolysis of wood;

By-products Physical state Brief Description

Charcoal Solid

Tar Liquid Highly viscous liquid

Pyroligneous liquor Liquid Condensation of vapours

Gasses, mainly CO and CO2 Gas

[4]

Gasification

Battele's Biomass Gasification System

“The process of heating wood in a chamber until all volatile gases such as CO, H2 and O2 are released from the wood and combusted. The emitted wood gasses are then superheated and mixed with air or pure oxygen for complete combustion. Gasification has the great advantage of having extremely high combustion efficiency and thereby generating minimal emissions”[3].

Gasification is a quicker process than pyrolysis and differs by “the presence of a limited quantity of air (20-80% stoichiometric)”. “The main product [of gasification] is syngas, composed of CO and H2, which can be of high quality if oxygen is used instead of air”[4].

Gasification is a quicker process than pyrolysis and differs by “the presence of a limited quantity of air (20-80% stoichiometric)”. “The main product [of gasification] is syngas, composed of CO and H2, which can be of high quality if oxygen is used instead of air”[4].

Liquefaction

Liquefaction is “a conversion process resulting in liquid products (methanol) from biomass by direct or indirect processes. Indirect, through gas phase; direct, without gas phase, for example by rapid pyrolysis”[3].

This is a fast process where pressurized water is used to “convert a liquid slurry of organic material into hydrocarbon oils and products....Direct liquefaction, or thermal depolymerization, has been successful in producing a liquid oil while the newer indirect liquefaction has had success producing syngas, ethanol, and methanol”[10].

This is a fast process where pressurized water is used to “convert a liquid slurry of organic material into hydrocarbon oils and products....Direct liquefaction, or thermal depolymerization, has been successful in producing a liquid oil while the newer indirect liquefaction has had success producing syngas, ethanol, and methanol”[10].

Biological Processes

Anaerobic Digestion

Basics of Anaerobic Digestion Process

Anaerobic digestion is a biological decomposition process where bacteria are used in controlled anaerobic conditions to break down biodegradable organic waste. The aims of the process can be summarised as: “sanitisation of the feed material and of any liquid discharged, [and] a net positive surplus generation of energy as a biofuel”[5]. The key by-product of anaerobic digestion is methane gas which is produced by the bacteria decomposing the organic waste and can be captured and utilised as a biogas. Carbon dioxide is also produced. “Anaerobic digestion is a net energy producing process (100-150 kWh, per tonne of input waste)”[6]

There are 3 main stages to anaerobic digestion, as shown in the process diagram, and at each stage different bacteria play a role.

There are 3 main stages to anaerobic digestion, as shown in the process diagram, and at each stage different bacteria play a role.

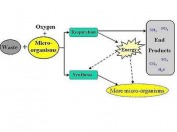

Aerobic Composting

Anaerobic Composting Process

Aerobic composting is similar to anaerobic digestion with the key difference being the presence of oxygen. The presence of oxygen means than different bacteria are employed in composting than in anaerobic digestion and that “composting represents an energy consuming process (around 30 - 35 kWh, is consumed per tonne of waste input) and is generally considered to be [a] commercial [process]”[6]. It should also be noted that “temperature, moisture content and good aeration are the main parameters for a good composting process”[7]. Again, as in anaerobic digestion, aerobic composting produces gases which can be captured and utilised for energy. In addition, “raw organic materials such as crop residues, animal wastes, food garbage, some municipal wastes and suitable industrial wastes, enhance their suitability for application to the soil as a fertilizing resource, after having undergone composting”[8].

Fermentation

“Fermentation is a biological process in which enzymes produced by microorganisms catalyze chemical reactions. These microorganisms digest sugars to produce the energy and chemicals they need for survival while giving off by-products such as carbon dioxide, organic acids, hydrogen, ethanol, and other products”[9], which are then collected and utilized for energy production. The digestion of the sugars by the bacteria is what is referred to as fermentation. For the purpose of this study, the fermentation of lignocellulosic material will be considered where ethanol is the main by-product.

[1] Stevens, C.V and Verhe, R.G. (2004) Renewable Bioresources, Scope and Modification for Non-Food Applications, John Wiley & Sons Ltd, Chichester, pg 120.

[2] Forest Encyclopedia Network, Thermochemical Conversion Processes, http://www.forestencyclopedia.net/p/p2/p1138/p1185/p1202/p1205 Accessed on 03.11.2009.

[3] Stevens, C.V and Verhe, R.G. (2004) Renewable Bioresources, Scope and Modification for Non-Food Applications, John Wiley & Sons Ltd, Chichester, pg 120.

[4] Stevens, C.V and Verhe, R.G. (2004) Renewable Bioresources, Scope and Modification for Non-Food Applications, John Wiley & Sons Ltd, Chichester, pg 172.

[5] Anaerobic Digestion, The AD Community, An Independent website, http://www.anaerobic-digestion.com/ Accessed on 03.11.2009

[6] Braber, K. Anaerobic Digestion Of Municipal Solid Waste: A Modern Waste Disposal Option On The Verge Of Breakthrough, Biomass and Bioenergy, Vol. 9, Nos 1-5. pp. 365-376.1995. Elsevier Science Ltd, Printed in Great Britain.

[7] Stevens, C.V and Verhe, R.G. (2004) Renewable Bioresources, Scope and Modification for Non-Food Applications, John Wiley & Sons Ltd, Chichester, pg 54.

[8] Misra, R.V., Roy,R.N. and Hiraoka,H., On-farm Composting Methods, Land and Water Discussion Paper 2, Food and Agriculture Organization of the United Nations, http://www.fao.org/docrep/007/y5104e/y5104e00.HTM Accessed on 03.11.2009.

[9] Forest Encyclopedia Network, Bio-chemical Processes http://www.forestencyclopedia.net/p/p2/p1138/p1185/p1201/p1219 Accessed on 03.11.2009.

[10] Forest Encyclopedia Network, Thermochemical Conversion Processes, http://www.forestencyclopedia.net/p/p2/p1138/p1185/p1202/p1210 Accessed 03.11.2009

Direct Combustion/Steam Turbine System picture courtsey of U.S. Department of Energy, Electricity Delivery & Energy Reliability, Technologies, Biomass Power http://www.eere.energy.gov/de/biomass_power.html Accessed on 03.11.2009.

Pyrolysis Process courtesy of Normal http://blogs.princeton.edu/chm333/f2006/biomass/bio_oil/02_chemistryprocessing_the_basics/02_processing/ Accessed on 03.11.2009.

Battele's Biomass Gasification System U.S. Department of Energy, Electricity Delivery & Energy Reliability, Technologies, Biomass Power

http://www.eere.energy.gov/de/biomass_power.html Accessed on 03.11.2009.

##########

Basics of Anaerobic Digestion Process U.S. Department of Energy, Electricity Delivery & Energy Reliability, Technologies, Biomass Power

http://www.eere.energy.gov/de/biomass_power.html Accessed on 03.11.2009.

Anaerobic Composting Process, Forest Encyclopedia Network, http://www.forestencyclopedia.net/p/p1217/ Accessed on 03.11.2009.

##########

[2] Forest Encyclopedia Network, Thermochemical Conversion Processes, http://www.forestencyclopedia.net/p/p2/p1138/p1185/p1202/p1205 Accessed on 03.11.2009.

[3] Stevens, C.V and Verhe, R.G. (2004) Renewable Bioresources, Scope and Modification for Non-Food Applications, John Wiley & Sons Ltd, Chichester, pg 120.

[4] Stevens, C.V and Verhe, R.G. (2004) Renewable Bioresources, Scope and Modification for Non-Food Applications, John Wiley & Sons Ltd, Chichester, pg 172.

[5] Anaerobic Digestion, The AD Community, An Independent website, http://www.anaerobic-digestion.com/ Accessed on 03.11.2009

[6] Braber, K. Anaerobic Digestion Of Municipal Solid Waste: A Modern Waste Disposal Option On The Verge Of Breakthrough, Biomass and Bioenergy, Vol. 9, Nos 1-5. pp. 365-376.1995. Elsevier Science Ltd, Printed in Great Britain.

[7] Stevens, C.V and Verhe, R.G. (2004) Renewable Bioresources, Scope and Modification for Non-Food Applications, John Wiley & Sons Ltd, Chichester, pg 54.

[8] Misra, R.V., Roy,R.N. and Hiraoka,H., On-farm Composting Methods, Land and Water Discussion Paper 2, Food and Agriculture Organization of the United Nations, http://www.fao.org/docrep/007/y5104e/y5104e00.HTM Accessed on 03.11.2009.

[9] Forest Encyclopedia Network, Bio-chemical Processes http://www.forestencyclopedia.net/p/p2/p1138/p1185/p1201/p1219 Accessed on 03.11.2009.

[10] Forest Encyclopedia Network, Thermochemical Conversion Processes, http://www.forestencyclopedia.net/p/p2/p1138/p1185/p1202/p1210 Accessed 03.11.2009

Direct Combustion/Steam Turbine System picture courtsey of U.S. Department of Energy, Electricity Delivery & Energy Reliability, Technologies, Biomass Power http://www.eere.energy.gov/de/biomass_power.html Accessed on 03.11.2009.

Pyrolysis Process courtesy of Normal http://blogs.princeton.edu/chm333/f2006/biomass/bio_oil/02_chemistryprocessing_the_basics/02_processing/ Accessed on 03.11.2009.

Battele's Biomass Gasification System U.S. Department of Energy, Electricity Delivery & Energy Reliability, Technologies, Biomass Power

http://www.eere.energy.gov/de/biomass_power.html Accessed on 03.11.2009.

##########

Basics of Anaerobic Digestion Process U.S. Department of Energy, Electricity Delivery & Energy Reliability, Technologies, Biomass Power

http://www.eere.energy.gov/de/biomass_power.html Accessed on 03.11.2009.

Anaerobic Composting Process, Forest Encyclopedia Network, http://www.forestencyclopedia.net/p/p1217/ Accessed on 03.11.2009.

##########